Live Process ML (PML) Models

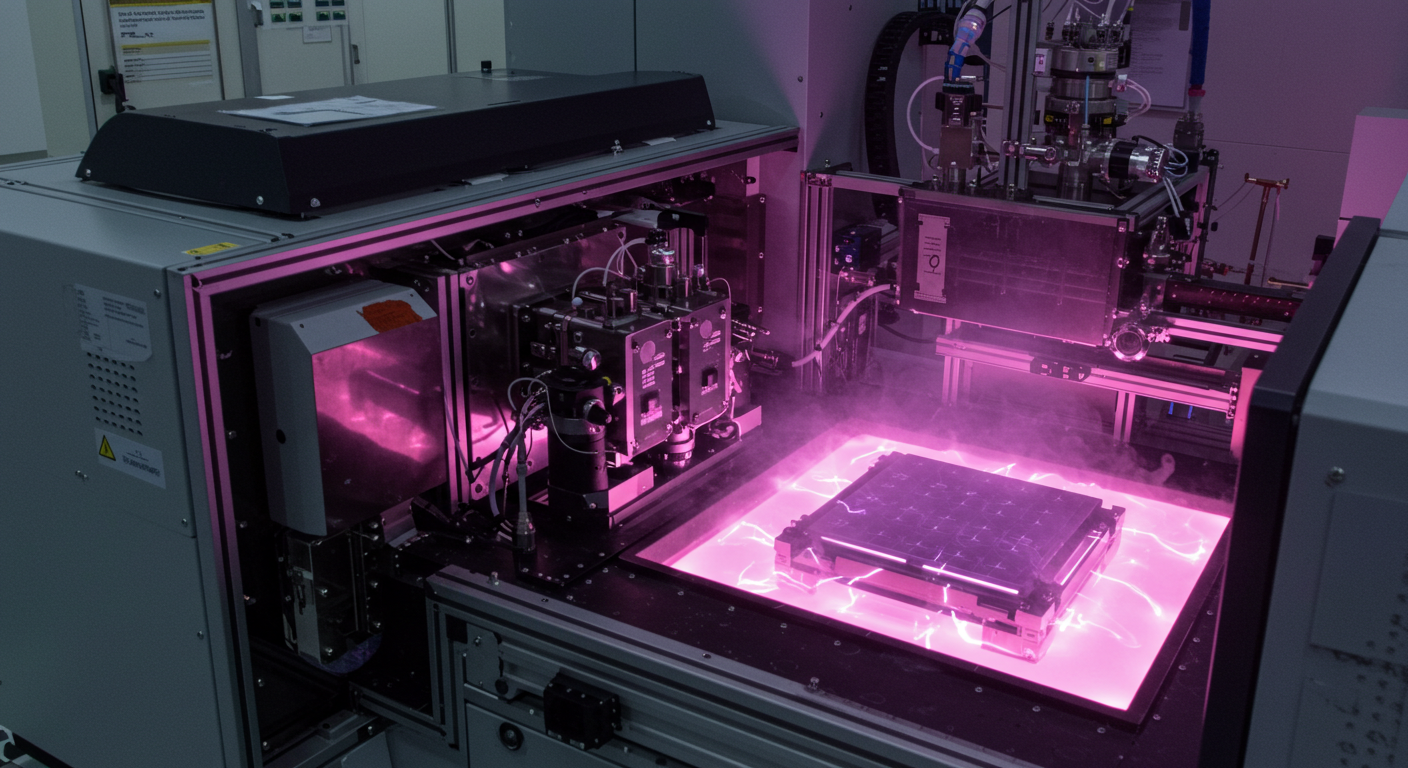

Plasma Etch Rate Prediction

A deep learning model trained on a physics-inspired surrogate equation representing plasma etching, a core process in semiconductor manufacturing. This demo shows how machine learning can support precise rate prediction and enable smarter process control on advanced equipment. Read more

CSTR Surrogate Model

A neural network model trained on the classic Continuous Stirred Tank Reactor (CSTR) system. This demonstration shows how even a well-understood process can benefit from data-driven simulation and rapid what-if analysis. Read more

PML Using Neural Networks

Modern manufacturing generates vast amounts of process data, but much of it remains underutilized. Neural networks provide a practical way to learn non-linear process behavior from historical runs and deliver fast, repeatable predictions that support better engineering decisions and lay the groundwork for intelligent automation.

Machine learning converts historical process data into predictive models that capture complex system behavior. When coupled with agentic AI, these models enable autonomous decision making and support the transition toward lights-off manufacturing.

Prediction is the start. The real value comes when models are connected to decisions, workflows, and automated action.

Note: These models are demonstrations. Production deployments can be customized to specific tools, recipes, constraints, and operational objectives.